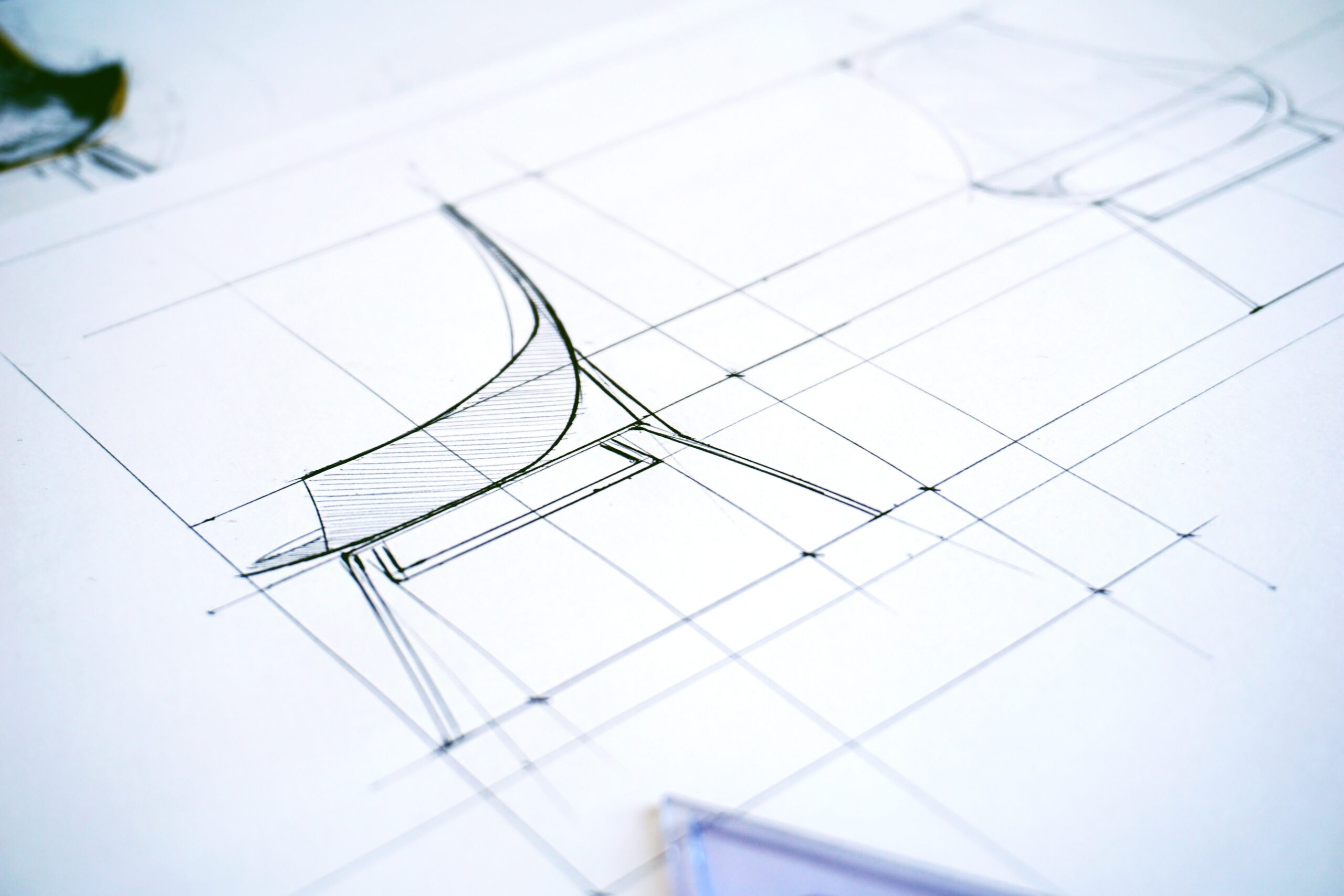

Product testing is often synonymous with lab testing in the quality control industry. This is because product quality testing is typically performed at a certified third-party laboratory, not at your supplier’s facility. On-site product testing can complement third-party inspection, but it’s not a substitute for testing in a professional lab.

Herein lies the key difference between product testing and product inspection processes. Product inspection typically involves visiting your supplier’s facility, or sending an inspector on your behalf, to check products on site. Whereas lab testing usually requires sending samples from your supplier’s facility to a laboratory for more controlled testing.

Is lab testing necessary for your product type?

Product quality testing isn’t necessary for all importers. But it can provide you with certified documentation attesting to your product’s safety and performance. And importers who need to comply with a specific regulation or set of regulations governing their product type will typically find product testing most helpful.

Consider the following when deciding whether to conduct product testing:

- Your product’s intended use and attributes: Some products inherently carry more risk than others. Some examples are children’s products or products that will be ingested or come in contact with food or beverages.

- Claims you’ve made in marketing your product: Have you made specific promises about your product’s quality or performance? Samples can be rigorously tested for durability or performance in comparison to leading competitors, also known as benchmarking.

- Regulations governing your product type in your market of sale: Mandatory safety regulations, like REACH or CPSIA standards, govern products that can potentially cause serious harm to end users. Compliance is a legal requirement in many markets.

Should you conduct product testing before or after production begins?

Importers commonly test two different types of samples at two different stages:

- Pre-production samples provided by the supplier before mass production begins

- Production units after mass production is underway

As with product inspection, testing products earlier in production, or even before production starts, can help you prevent issues from affecting the majority of your order.

Always request a product sample before mass production begins when working with a new supplier or manufacturing a new product, regardless of whether you plan to test it in a lab.

Obtaining a product sample helps you ensure your supplier understands your requirements and can meet your quality standards. Some importers even request a product sample when negotiating with suppliers to assess and compare potential suppliers’ production capabilities.

If you plan to test units from mass production, quality control inspectors can often pull a few production units during inspection and then either:

- Perform some basic on-site testing at that factory; or

- Seal and send the samples to a lab for testing there

Having your inspectors pull samples at the factory ensures the samples are truly random and representative of the entire order. Relying on factory staff to pull samples carries the risk that workers will “cherry pick” samples known to be compliant, in better condition or otherwise not representative of the order.

Sending a product sample to a laboratory for testing can help you verify materials and components used in the sample and assess safety and performance. You may need to test each SKU, especially if they are manufactured with different materials. But testing just a few units of each SKU is usually adequate, as materials and production processes are typically consistent across an order.

Can your supplier reliably perform lab testing at their own facility?

It’s true that some factories have sophisticated facilities to accommodate certain kinds of on-site lab testing. But while valuable, it’s important not to overestimate the accuracy of these test results from such a lab.

Factory labs usually are not certified by official accrediting bodies, such as the ANSI-ASQ National Accreditation Board (ANAB) or the International Accreditation Service, and certainly cannot be considered independent third parties. In several markets, like the EU and United States, national governments require these accreditations for brands to import and sell products there.

Another important consideration is the competence and experience of the workers carrying out testing. Factory employees generally won’t be as qualified and reliable as the skilled technicians employed by more professional, accredited testing labs.

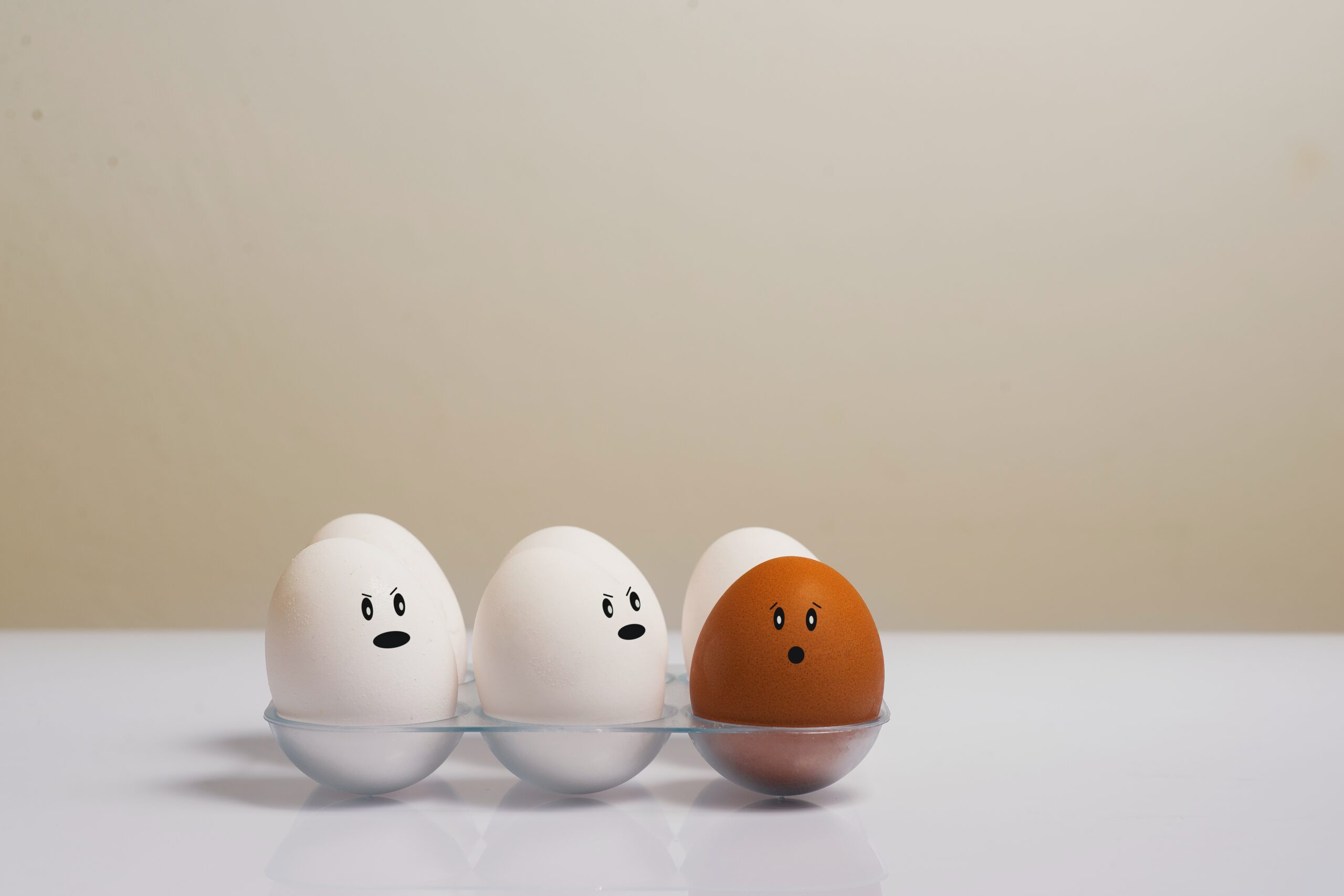

Fraudulent product testing results from a factory

Just as factory self-inspection presents a conflict of interests, so too does relying on your manufacturer to test their own products. Factories might even forge favorable testing results or desired certifications. For example, one furniture importer we’ve worked with told us their factory openly suggested applying fake labeling to “certify” their office chair cushions were flame retardant.

Testing laboratory TUV Rheinland has actually published a “blacklist” of such fraudulent suppliers who have used their certification mark without authorization, falsified a test report or created a fake report or certificate.

The dangers of relying on previous test reports

Your supplier might provide you with previous test reports or certificates as evidence of their capabilities and compliance. It’s a great idea to ask for these reports and assess them when choosing a supplier. But you should never rely on these previous reports for the actual compliance of your products.

Aside from fraudulent concerns, there’s no guarantee that a supplier’s manufacturing processes or materials haven’t changed since issuing a previous report. Testing your product samples in an independent lab will help ensure the actual products you’re responsible for are compliant and safe for use.

Article Source: Intouch-quality