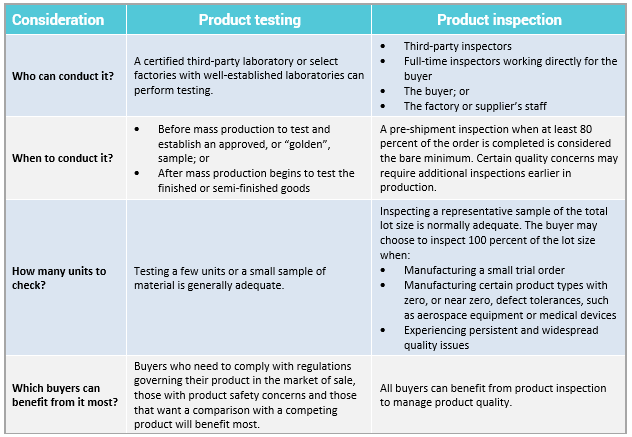

Product inspection is the process of checking goods for compliance with your specifications and requirements. Generally conducted at the factory manufacturing your product, the product inspection process primarily focuses on checking the appearance, construction and basic function of a product.

The other key purpose of product inspection is to help you identify and address any quality defects in your products before they reach your customers. Inspectors often use an acceptance sampling method like AQL to inspect a random sample of the total order quantity. The inspector can typically classify quality defects based on their severity and issue a clear “pass” or “fail” result for the order using AQL.

Who can conduct product inspection?

When manufacturing abroad it’s easy for factory staff to misunderstand your requirements and manufacture products that don’t meet your specifications. That’s why many importers find that relying on their factory to conduct product inspections isn’t always a reliable way to manage product quality.

Factories’ own internal QC staff rarely provide detailed reporting of the product inspection process that importers need to assess an order. Instead, importers serious about managing product quality usually turn to one of the following alternate methods which SourceX Provides:

- Hire a third-party inspection company: Independent inspection firms can often inspect a wide range of products and issue a comprehensive report for a reasonable fee. They typically follow industry-standard inspection processes and should have strict integrity policies to ensure reliable results.

- Hire full-time inspectors: These are local employees hired by your company and paid on a salary basis to inspect your products. In order to hire local employees, you’ll often need the resources to legally set up an office abroad.

- Send a company representative abroad or inspect yourself: You might feel you can inspect products better according to your own standards and requirements. But high time and travel costs can make this an impractical option if you need frequent inspections for large order volumes.

Most suppliers in Asia are familiar with each of the above product inspection approaches. Notify your supplier about your inspection requirements when placing your order, including when inspection must occur and who will conduct it. This will help your supplier to prepare for inspection and minimize any pushback before shipment.

When should you conduct product inspection?

Final inspection, or pre-shipment inspection (PSI), occurs when your supplier has completed 80 percent or more of your order. This is the most common time to inspect and is the option QC professionals typically recommend as the bare minimum for consumer products.

The main drawback of PSI is it often happens too late to address any of the quality defects or issues the inspector finds in the shipment. Depending on the types of problems found and how soon the goods need to leave the factory, there may not be enough time to replace or rework the affected units. PSI also does little to prevent defects in an order.

Product inspection can offer different benefits at different production stages. Inspecting earlier in production can help you identify any quality issues before they affect the majority of an order. Incoming quality control on raw materials or components and a during production inspection when 15-80 percent of the goods are manufactured are two common options available to importers.

Article Source: Intouch-quality

Related: What is Product Testing?